Features and Benefits:

» Easy and Simplify Field Maintenance

» Field Replaceable Trim which ensures complete system can be removed or change out in Field

» Vent Chamber separated double sealing to isolate the BOP operating system from well bore pressures

» Metal to Metal contacts is completely removed by a high strength Bearing, whereas all moving parts wears from the operating system may be reduced effectively.

» Working Pressure: 2000psi,3000psi,5000psi, 10000psi,15000psi

» Size: 7-1/16",9",11",13-5/8",16-3/4", 18-3/4",20-3/4",21-1/4"

» Production Spec Levels: PSL1 thru PSL 4

» Temperature Rating: T75, T25, T0

»

To NACE MR-01-75 for H2S Service

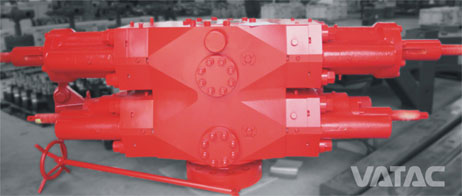

Ram Blowout Preventer

The

Vatac Ram Blowout Preventers are designed to close the well and prevent free

blowouts that may occur when drilling and bringing in oil and gas wells which

is available in single and double Ram configuration, manufactured strictly according

the most updated international standards, available in sizes from 7-1/16" thru 21-1/4" and

pressures of 2,000PSI-15,000PSI.

The

Vatac Ram Blowout Preventer offers a unique combination of benefits in safety,

economy, reliability, fast and easy service & maintenance, long service

life, and reduced space. With an advantage and features as below:

» Sealing can be maintained even with the loss of BOP operating pressure by energizing well pressure on the ram

» Ram assembly provides a pressure energized seal with maximum contact area with the drill pipe, casing, or tubing, providing a lower rubber pressure to increase a seal life properly

» The ram assemblies are locked manually In shut off position.

» Oval ram and cavity design reduces stress effectively from the BOP body

» Drill pipes, tubing or casing is pushed to a center position by Centering Guides by special machining practice

» Bonnet is separated by the hydraulic opening bonnets from the body to ensure the ram assembly for a quick change out

» Fast and reliable closure of the well bore is realized by the BOP hydraulic operating systems, providing a quick ram change-out

» Two sealing systems of well pressure and hydraulic fluid pressure is well separated beside hydraulic fluid pressure

» Structures in Bonnets opened, locking screws out - Bonnets closed, locking screws in

» Outlets: 2 1/16" flange or studded flange (other dimension on request)

» Hydraulic system connection: 1"