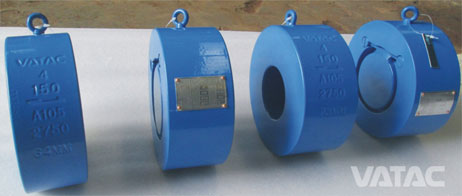

Wafer check valve, swing check valve, lubricated plug valve is one main product range from Vatac, we offer a broad line of wafer checks in both Single Disc & Dual Plate, also in Tilting Disc. Fabricated from Cast or Ductile Iron, Carbon or Stainless Steel, specials like Duplex, Alum. Bronze. Standards to the most updated international standards

VATAC WAFER CHECK VALVE DESIGN FEATURES ● LAPPED BODY & DISC SEATS

The heart of each valve is the seat/seal interface. Our valves are manufactured using the most updated machining methods and equipment to achieve maximum flatness with a fine lapped finish. The end result is valves that easily meet and exceed test requirements for metal-seated check valves ● RETAINERLESS BODY DESIGN: The Vatac dual plate check valve’s body is essentially a short, heavy wall cylinder with no holes through the body wall. There is no need for retainers and leakage to the outside is impossible. ● INTRINSICALLY FIRE SAFE: With no drilling through the body wall, the Vatac dual plate check valve is intrinsically fire safe. ● HIGH TORSION SPRING: For potentially severe applications, a high torsion spring ensures the vatac wafer check closes as quickly as possible. ● SUPERIOR HINGE DESIGN: In order to eliminate seat wear during the opening cycle, all vatac wafer dual plate check valves incorporate clearance between the hinge pin and holders, or hinge pin and disc bore. This clearance allows the disc assembly to lift off the seat prior to disc rotation preventing the heel of each disc from scraping across the body seat. Conventional designs have an oversize bore in the discs or bearings, allowing constant side to side movement of discs and increased chance of premature failure.

Vatac offers a broad line of Wafer Check Valves covering Dual Plate, Single Disc, Fully Lugged & Tilting Disc Types, all items are designed and manufactured strictly to International Standards ASME B16.34 or Equivalent.

● Retainerless Body Design: There is no need for retainers and leakage to the outside is impossible.

● Lapped Body & Disc Seat: Easily meet or exceed test requirements for metal-seated check valves.

● High torsion spring loaded design: Ensuring a low craking pressure

● Light Weight and small Space: Saving a lot in cost and installation

STANDARDS COMPLIANCE AND MAIN FEATURES:

● Design & Manufactured to ASME B16.34 or Equivalent ■ P.T Ratings to ASME B16.34

● Face to Face Dimensions to ASME B16.10 ■ Flanged Ends to ASME B16.5

● Butt-weld Ends to ASME B16.25 ▲ Valves Marking to MSS SP-25

● Inspect & Tested to the most updated international standards

● Sizes Ranges from 1/2” thru 60”.

● Structured in One Piece Union Body

● Pressure Ratings from Class 150 to Class 2500, PN16 to PN420

● Ends Connections in Flanged R.F or RTJ, Wafer, Fully Lugged and Grooved

● A variety of body and trim material is offered, including carbon steel ASTM A216 WCB, WCC; Cast or Ductile iron A126, GG25, A536 or GGG50, Low Carbon Steel LCB, LCC, Alloy Steel WC6, WC9, C5, Stainless Steel CF8, CF8M, CF3, CF3M, Duplex & Super Duplex Steel A890 GR. 4A, 5A or F51, Special Materials in Monel, Alu. Bronze C95800, 95600 etc. Coatings may be provided for added corrosion or wear resistance. Hard-facing and weld overlays may also be supplied. Seats Options with metal-to-metal or bubble-tight resilient.

● Optional Bypass system & Counter-weight Assembly.

Please feel free to contact with Vatac Sales team or your local Representatives for other optional special requirements