Needle valves are usually used in flow meterings, especially when a constant, calibrated, low flow rate must be maintained for some time, such as the idle fuel flow in a carburetor. Vatac offers shutoff and regulating needle valves for both general and severe services. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger, on the end of a screw, which exactly fits this seat. As the screw is turned and the plunger retracted, flow between the seat and the plunger is possible; however, until the plunger is completely retracted the fluid flow is significantly impeded. Since it takes many turns of the fine-threaded screw to retract the plunger, precise regulation of the flow rate is possible.

The virtue of the needle valve is from the vernier effect of the ratio between the needle's length and its diameter, or the difference in diameter between needle and seat. A long travel axially (the control input) makes for a very small and precise change radially (affecting the resultant flow). Needle valves may be used in vacuum systems, when a very precise control of gas flow is required, at low pressure, such as when filling gas-filled vacuum tubes, gas lasers and similar devices.

Vatac needle valves are designed for use in general purpose applications to isolate or vent system media. The hardened stainless steel, non-rotating needle promotes leak-tight shutoff and long service life. The valve stem threads are isolated from the media. Compact design, Stainless steel stop pin, Antitamper and lockable handle features available Suitable for sour gas service; materials for wetted components selected in accordance with NACE standard MR0175/ISO 15156.

Vatac offers a broad line of needle shutoff and regulating valves to control flow in general- and severe-service applications.

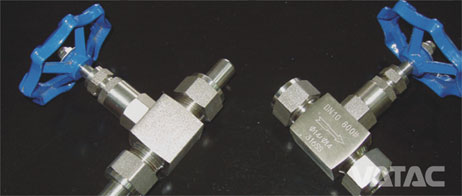

▲ Integral-bonnet and nonrotating-stem needle valves

▲ Severe-service union-bonnet and instrumentation blowdown valves

▲ Screwed-bonnet needle valves ▲ General utility and forged-body needle valves

▲ High-pressure needle valves ▲ Gauge valves and rising plug valves

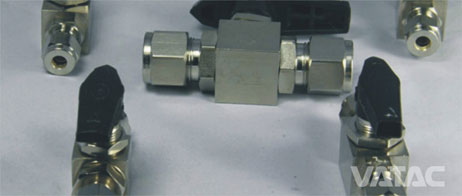

▲ Compact gauge valves ▲ Compression valves for the sanitary industries

Vatac offers compact needle valves in a full range of sizes, configurations, and materials for a variety of applications.

THE VATAC NEEDLE VALVES DESIGNING FEATURES:

▲ Structured in in Screwed Bonnet or Union bonnet suitable for general and servere applications.

▲ Forged Body in Carbon Steel, Stainless Steel, or Duplex

▲ Stainless Steel Trim Gr. 304 or Gr. 316 as standard

▲ Sizes: DN8 through DN50

▲ Body Styles: Welded or Threaded Ends

▲ Pressure Class: up to 6000PSIG or PN640

STANDARDS COMPLIANCE:

▲ ASME B16.34 ▲ ASME B16.25 ▲ ASME B1.20.1 ▲ ASME B16.11 ▲ MSS SP-25 ▲ ISO 5208

▲ Sizes: DN8 through DN50

▲ Body Styles: End connections Welded or Threaded Ends

▲ Pressure Class: up to 6000PSIG or PN640

The Vatac Complete Line of Needle Valves have been solving many fluid control problems in the general and Servere service industrial applications for over 30 years. Today Vatac Technologies is putting that experience to work for you in more ways than ever before- meeting your changing needs with dependable Vatac Needle Valves and accessories.