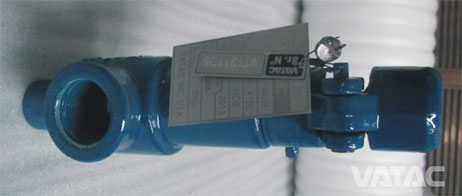

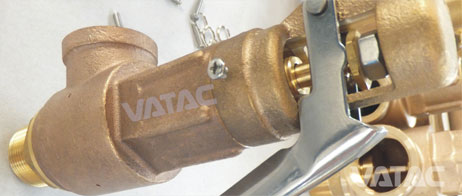

Vatac Safety Relief valves are factory set, tested, sealed and tagged to service your specific appli-cation in Air, Steam, Gas or Liquid areas. The pressure relief or pop off point are set in accord-ance to the safety and capacity requirements of DIN, ASME Norms. The Safety Valve is a valve mechanism for the automatic release of a gas from a boiler, Pressure Vessel, or other system when the pressure or temperature exceeds preset limits. It is part of a bigger set named Pressure Safety Valves (PSV) or Pressure Relief Valves (PRV). The other parts of the set are named Relief Valves, safety relief valves, pilot-operated safety relief valves, low pressure safety valves, vacuum pressure safety valves.Safety valves were first used on steam boilers during the industrial revolution. Early boilers without them were prone to accidental Explosion. Safety valves also evolved to protect equipment such as pressure vessel (fired or not) and heat exchangers. Safety valve term should be limited to compressible fluid application (gas, vapor, steam).

The ASME / ANSI PTC25.3 standards applicable to the USA define the following generic terms:

● Pressure relief valve - A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening 'pop' action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application. This is a general term, which includes safety valves, relief valves and safety relief valves.

● Safety valve - A pressure relief valve actuated by inlet static pressure and characterised by rapid opening or pop action, Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

● Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid. In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Vatac offers a broad line of Pressure Relief Valves covering Full Lift Safety Relief, Pilot-operated Safety Relief Valve (POSRV), Low Pressure Safety Valve (LPSV), Vacuum Pressure Safety Valve (VPSV), Low and Vacuum Pressure Safety Valve (LVPSV).

STANDARDS COMPLIANCE:

▲ ASME PTC 25.3, EN ISO 4126

▲ ASME B16.10, EN558-1 / DIN 3202

▲ ASME B16.5a, ASME B16.11, ASME B1.20.1, DIN 2543~2545, EN 12627

▲ ISO 5208, DIN 3230, MSS SP-117

▲ Sizes: DN15 through DN300

▲ Body Styles: End connections Flanged, Welded or Threaded Ends

▲ Pressure Class: ANSI CL150 to CL1500, PN16 to PN260

The Vatac Safety Relief valves have been solving fluid control problems in Steam, Boiling and other general industrial applications for over 30 years. Today Vatac Technologies is putting that experience to work for you in more ways than ever before- meeting your changing needs with dependable Vatac Safety Reliefe valves and accessories.